Cement-based repair mortars can be used for various purposes. Calcium aluminate cement can also be preferred as a repair mortar due to its suitable properties. Cement admixtures help optimize the performance of cement for specific applications. These admixtures can be either organic or inorganic compounds. In this article, we will discuss the use of organic acid-based admixtures and their effects on the compressive and flexural strength of ternary systems, based on experimental results.

What are Repair Mortars? What are they good for?

Repair mortars are high-strength, cement-based ready-mix products. They are used to repair various types of structural damage. Repair mortars are frequently preferred due to their ease of application and high durability. Pot life and setting times can be adjusted according to specific application needs. When using repair mortars, the properties of the material must be carefully considered.

The required properties of materials used for repair include:

- Rapid setting and strength development,

- High adhesion to the application surface,

- Compatibility with the concrete substrate,

- Dimensional stability,

- Resistance to abrasion..

Why to Use Calcium Aluminate Cements in Repair Mortars?

Calcium Aluminate Cements (CACs) meet all requirements of materials to be used for repairing purposes. CACs;

- develop high early strength,

- are resistant to sulfate attack,

- are used in refractory concretes due to their high-temperature resistance,

- provide excellent wear and impact resistance.

- are used in construction chemicals such as self-leveling screeds and ceramic adhesives.

Thanks to these properties, CACs have strong potential for use in repair mortars. For more information, please refer to our article titled Everything You Need to Know About Calcium Aluminate Cement.

What is the Effect of Citric Acid and Lactic Acid Admixtures on Compressive and Flexural Strength in Ternary Systems?

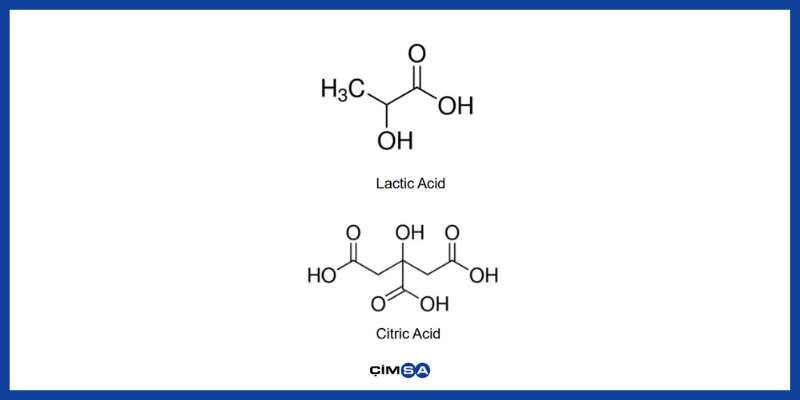

Citric acid and lactic acid are organic admixtures from the carboxylic acid group. Citric acid acts as a retarder by delaying hydration, as negatively charged citrate ions are adsorbed onto the positively charged surfaces of Portland cement particles. This delay in hydration prolongs the setting time and reduces early strength. Therefore, citric acid is classified as a retarding chemical admixture. Retarders are used to prevent undesirable outcomes when large volumes of concrete are transported over long distances in hot weather conditions. On the other hand, lactic acid can increase the initial heat of hydration, accelerate hardening, and promote early strength development. Hence, it functions as a set-accelerating chemical admixture. The increase in hydration heat also allows it to act as an antifreeze.

In cold weather, concrete without admixtures sets more slowly. Early strength is low, and demolding takes longer. As a result, more time is required for curing. When a set-accelerating admixture is used, these effects are mitigated..

Figure 1. Lactic Acid and Citric Acid

- Tests:

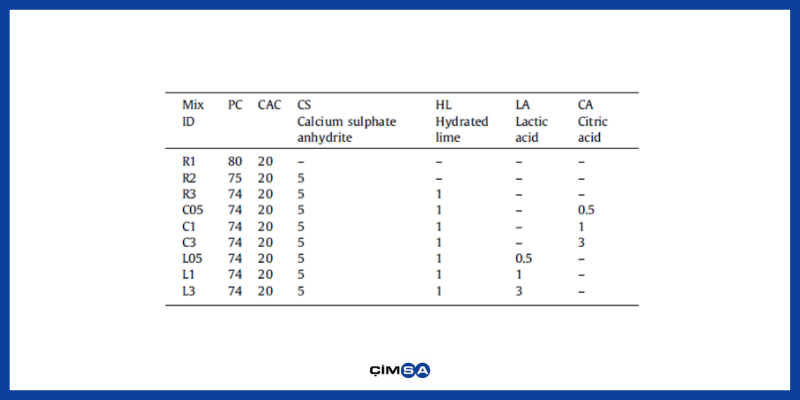

The formulation for a ternary system mortar used in the test is given in the following table.

Table 1. Mortar Recipes Used during the Test

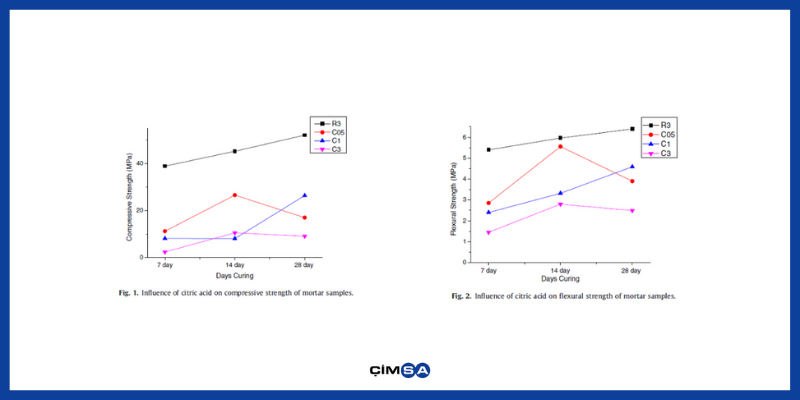

Compressive and Flexural Strength: Citric Acid

Figure 2. A) The Effect of Different Ratios of Citric Acid Admixture on the Compressive Strength of Mortars, B) The Effect of Different Ratios of Citric Acid Admixture on Flexural Strength

During the tests, the effects of citric acid with different admixture ratios on compressive and flexural strength were investigated. In line with the results obtained in the figures above, we can comment as follows.

- Specified in the figures above and in the mortar recipe, C3 contains 3% citric acid admixture. On the other hand, R3 is a mixture that does not contain citric acid admixtures. Considering the compressive and tensile strengths of the two mixtures, the 7-day compressive and flexural strengths of the C3 mixture was observed to decrease to 6.22% and 26.85% of the R3 mixture, respectively.

This proves that the citric acid admixture prevents cement hydration by reducing the flexural and compressive strength at all ages.

- Specified in the figures above and in the mortar recipe, C05 contains 0.5% citric acid admixture. The compressive and flexural strengths of this mixture reached 26.5 MPa and 5.56 MPa, respectively, in 14 days.

In other words, since free citric acids decrease at early ages, we can conclude that the effect of citric acids on reducing the solubility of C3S (alite) and phases with aluminate is less at 14-day and 28-day strengths.

- Specified in the figures above and in the mortar recipe, C1 contains 1% citric acid admixture. Unlike the others, no change was observed in the 7-day and 14-day compressive strength of this mixture. However, an increase was observed at 28 days.

The reason for this increase is the microstructure change in the presence of citric acid.

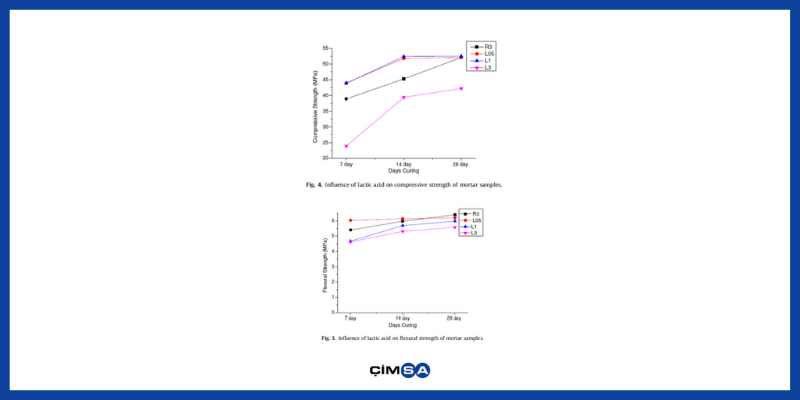

Compressive and Flexural Strength: Lactic Acid

Figure 3. A) The Effect of Different Ratios of Lactic Acid Admixture on the Compressive Strength of Mortars, B) The Effect of Different Ratios of Lactic Acid Admixture on Flexural Strength

During the tests, the effects of citric acid at different admixture ratios on compressive and flexural strength were investigated. Based on the results shown in the figures above, the following observations can be made:

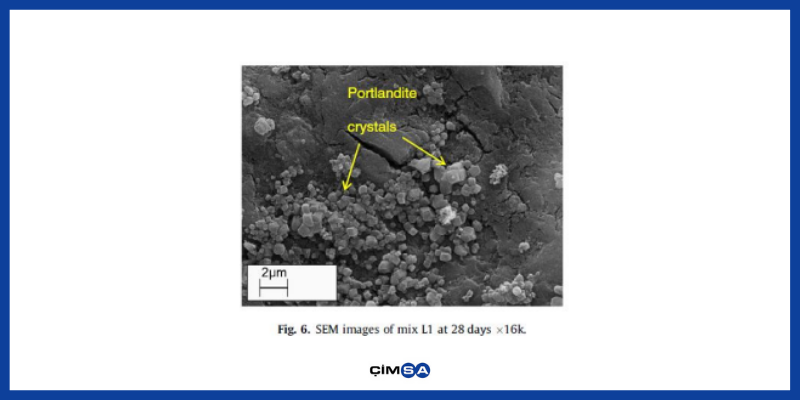

- As specified in the figures above and in the mortar mix design, L05 contains 0.5% lactic acid admixture, while L1 contains 1% lactic acid admixture. An increase was observed in the 7-day and 14-day compressive strengths of both admixture ratios. Furthermore, the 28-day compressive strength is the same as the reference R3 mixture that contains no admixture. The reason for the increase in strength is the increase in the percentage of the portlandite phase in crystal form.

Figure 4. SEM image of 28-day L1 Mixture

- Specified in the figures above and in the mortar recipe, L3 contains 3% lactic acid admixture. Once the lactic acid admixture ratio is increased to 3%, the compressive strengths fall below the reference mixture (R3).

The reason for the decrease is that the lactic acid admixture blocks residual hydrates and prevents their formation.

- Flexural strengths were almost the same at all mixing dosages.

Test Results

- The compressive and flexural strengths of Portland/calcium aluminate cement mixtures generally decrease with the addition of citric acid. Addition of 1% citric acid increases portlandite formation. At citric acid dosages above 1%, the acid is absorbed into the cement particles and inhibits the formation of hydration products. Therefore, the 28-day strength is higher than that of mixtures containing 0.5% and 3% citric acid.

- Low amounts of lactic acid (0.5% and 1%) caused the 7-day and 14-day compressive strengths to increase by approximately 20% compared to the reference, while the 28-day compressive strengths did not change. The flexural strength changes were quite small due to the addition of lactic acid. However, portlandite formation decreased with the addition of 3% lactic acid. This resulted in a decrease in the 28-day strength, which may be associated with the decrease in portlandite formation.

Why are Acid Admixtures Important?

Repair mortars can be customized in terms of pot life and setting time depending on their intended use. The use of acid admixtures is effective in modifying these properties, as they are a type of chemical admixture used in cementitious systems. These admixtures are used to improve some properties of concrete or to increase the adaptation of cementitious systems to various application areas. Acid admixtures play an important role in maintaining concrete quality during mixing, transportation, curing, and under adverse weather conditions. In this article, we discussed the effects of “Citric Acid” which has a retarding effect and “Lactic Acid” which has a set accelerating effect on compressive and flexural strengths when used in different ratios.

References: