Calcium aluminate cements are a special class of strong, high-performance heat-resistant cements. Calcium aluminate cements (CAC) have different chemical, physical and mineralogical properties than those of Portland cements (OPC). The primary raw ingredients of Portland cement are limestone and clay. The primary oxides derived from the raw materials are CaO and SiO2. In the production of calcium aluminate cement, on the other hand, bauxite is the raw material and source of alumina. The primary oxide is Al2O3.

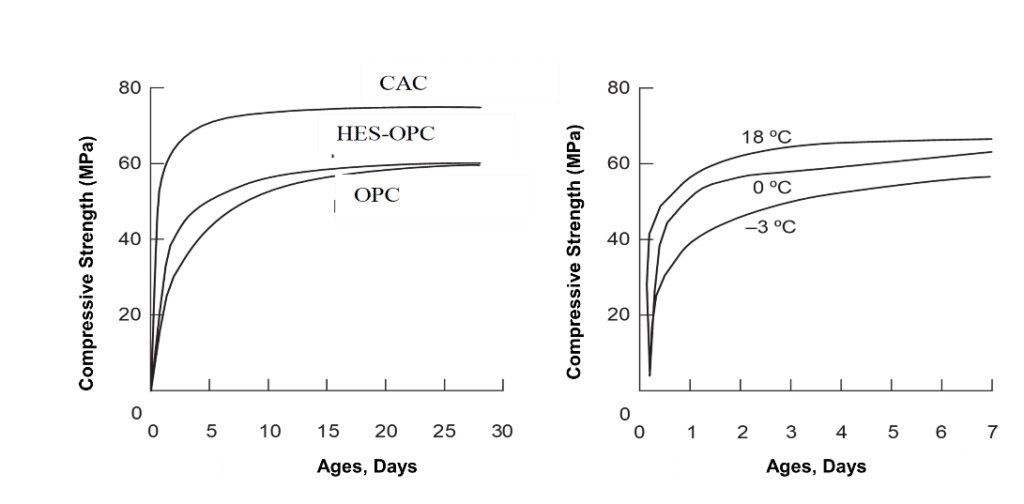

The most well-known property of calcium aluminate cement is that strength develops in 24 hours. In other words, the strength achieved by Portland cement in 28 days can be achieved with calcium aluminate cement in 24 hours. Strength development with gray and white Portland cements, on the other hand, takes 28 days to complete.

Figure 1. CAC and OPC raw materials

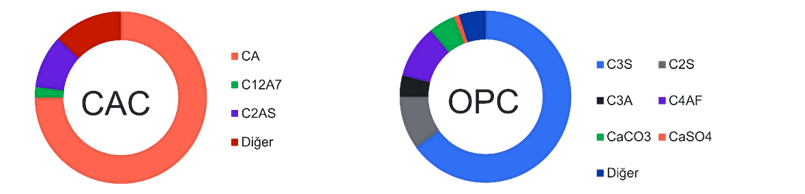

Figure 2. Fundamental chemical content of CAC and OPC

What are the Fundamental Differences of Calcium Aluminate Cement?

Because the raw materials used in production are different, calcium aluminate cement and Portland cements have different mineralogical properties. All calcium aluminate cements primarily contain mono-calcium aluminate, in other words, the CA phase. Portland cements (OPC), on the other hand, contain C3S and C2S phases as a result of the raw material components.

Figure 3. Calcium aluminate cement (CAC) and Portland cement phases

Differences between calcium aluminate cement and Portland cement:

- When Portland cements react with water to create C2S and C3S phases with calcium and silicium oxides, the result is the formation of C-S-H and C-H hydrates.

- When calcium aluminate cement is mixed with water it basically forms calcium aluminate hydrates by creating monocalcium aluminate (CA) with calcium and aluminum oxides.

Where is Calcium Aluminate Cement Used?

This difference in the structure of calcium aluminate cement provides a number of advantages, and we see it used for a variety of purposes in different parts of the world. Calcium aluminate cements are used when the performance, durability and early strength properties of Portland cement may be inadequate. They are used in the following applications:

- As the primary binding agent in concrete and refractory applications that must withstand high temperatures

- In tunnels, road applications and slab on grade that require a high level of initial strength in cold weather

- In self-leveling floor coatings

- Quick setting ceramic adhesives and joint fillers

- Quick setting repair mortar applications

- In structures that are exposed to intensive chemical attack such as chicken farms, dairies and leather processing plants

- In pipe linings that are exposed to biogenic corrosion.

What are the Properties of Calcium Aluminate Cement?

Calcium aluminate cement has different variables than Portland cements due to its structure. The primary phase in all types of calcium aluminate cement is the monocalcium aluminate (CA) phase, which is responsible for the cement’s fundamental properties. Another phase is the mayenite phase (C12A7), which quickly reacts with water and also plays an important role in the nucleating of calcium aluminate hydrates.

Because of the high reactivity of the CA phase, which is the primary cement component, initial strength development is very high. Therefore, it achieves strength under curing conditions below zero (Figure 4) much better than Portland cement and is very attractive in cold weather applications.

Figure 4. CAC and OPC strength development at different temperatures.

Calcium aluminate cement differs depending on the amount of alumina it contains. Products that contain a minimum of 40% alumina (e.g., Isıdaç40, Recipro40) maintain their integrity at temperatures up to 1250 degrees while products that contain a minimum of 50% alumina (e.g., Recipo50, Refro50) do not degrade at temperatures up to 1450 degrees. Due to these properties, it is preferred as a primary binder in refractory applications such as the glass, iron and steel industries, as well as for coating smokestacks.

Calcium aluminate cements have high final strength, which is achieved in 24 hours. These properties are why it is preferred in construction chemical products. Certain construction chemical products such as leveling screed and grout mortar are expected to be ready to use in as little as 6 hours. In these types of applications, the high early and final strength of calcium aluminate cement is preferred.

Because cements have an alkaline structure, the most corrosive and damaging environments are acidic. All cements, including calcium aluminate cement and Portland cement, are attacked in acidic environments. However, CA, the primary phase in calcium aluminate cement, reacts with water to create the CAH10 phase, which is transformed to the C2AH6 phase and AH3 gel, and these have a more stable structure over time at higher temperatures. This stable phase structure demonstrates resistance to acid. This is the reason that it is preferred for concrete and repair mortar in areas exposed to acids such as sewage pipe coatings, chicken farms and the leather industry.

How is Calcium Aluminate Cement Used?

Another area in which calcium aluminate cement performs well is its resistance to corrosion. CAC concretes are also used in situations of excessive wear from industrial vehicles and that result in spills of mild acid. Resistance to thermal shock is also important in some situations, such as in foundries and cryogenic facilities.

Calcium aluminate cement-based repair concrete (Figure 5) was used in an area of about 100 m2 at the Çimsa calcium aluminate cement production plant in Mersin. The aim in this job was to achieve 30 MPa in 4 hours to satisfy the need for initial strength in projects that require rapid concrete pouring such as factories and city roads.

Figure 5. Çimsa Concrete Road Construction

Three different concrete designs were prepared in this study and the detailed recipe design is provided in Tables 1 and 2.

The design of Experiment 1 used the following additives for each cubic meter: 120 grams of retarder and 520 grams of plasticizer. In Experiment 2, an additional 600 grams of polypropylene fiber per cubic meter was also included with the other additives. In the first blend, there was a loss of initial strength under pressure due to the additives even though the setting time was longer. The fiber was added to the concrete blend due to the risk of cracking.

In the Experiment 3 concrete blend, the additives were removed from the recipe to enhance early strength gains. In this study, rapid hardening was observed, and the workability time was shorter than expected. In order to prevent problems that might occur in the concrete mixer, fiber and water were added to the concrete when it was poured.

Results of the Experiment

In conclusion, the additives delayed setting time in the calcium aluminate blends and so increased workability time. Therefore, it can be reliably used in applications that require workability and where there is no expectation of initial strength. In concrete applications that require early strength, the product must be used without additives. Workability time is shorter in applications where early strength is expected. As is the case with all concretes, in experiments with concrete using aluminate cement, one of the most important issues is curing, which becomes more relevant as initial strength increases. The curing process must also commence early.

In recent years, it has proven itself as a solution in repair cements that require early strength. The first example of these special concretes was successfully implemented in an area exposed to high temperatures at the Iron-Steel plant in Izmir in 2013. The use of calcium aluminate cements in the ready-to-use concrete sector is expected to become more widespread as construction speed and performance requirements increase in the coming years.

Sample recipes

| Materials | Experiment 1 | Experiment 2 | |

| Amount of CAC (kg/m3) | 400 | 400 | |

| Amount of water (kg/m3) | 160 | 160 | |

| Water/Cement | 0.40 | 0.40 | |

| PP fiber (kg/m3) | 0 | 0.6 | |

| Additive 1 | 1.2 | 1.2 | |

| Additive 2 | 5.2 | 5.2 | |

| 0-4 Aggregate (kg/m3) | 938 | 938 | |

| 5-12 Aggregate (kg/m3) | 357 | 357 | |

| 12-22 Aggregate (kg/m3) | 585 | 585 | |

| Initial Precipitation (cm) | 12 | 10 | |

| Strength under Pressure (MPa) | 6 hours | 0.0 | 0.0 |

| 24 hours | 29.7 | 25.8 | |

| 2 Days | 31.2 | 33.1 | |

| 7 Days | 35.9 | 37.1 | |

Table 1 CAC concrete recipe design with additives

| Materials | Experiment 3 | |

| Amount of CAC (kg/m3) | 400 | |

| Amount of water (kg/m3) | 188 | |

| Water/Cement | 0.47 | |

| PP fiber (kg/m3) | 0.6 | |

| 0-4 Aggregate (kg/m3) | 940 | |

| 5-12 Aggregate (kg/m3) | 295 | |

| 12-22 Aggregate (kg/m3) | 608 | |

| Initial Precipitation (cm) | 10 | |

| Strength under Pressure (MPa) | 6 hours | 30.2 |

| 24 hours | 33.4 | |

| 2 Days | 37.9 | |

| 7 Days | 45.1 | |

Table 2 CAC concrete recipe design without additives

Note: The pressure strength values provided above are the strength of 15×15 cm3.

References Used

2. Calcium Aluminate Cements: Raw Materials, Differences, Hydration and Properties

3. Lea’s Chemistry of Cement and Concrete, 4th Ed

4. Durability of ternary binders based on Portland cement, calcium aluminate cement and calcium sulfate